Bespoke 3D printing designs

3DClever produce high-quality 3D printed products for you and your team. See your design concepts be transformed into actual working models. Contact us for a FREE initial assessment, without obligation.

Bespoke designs for your requirements

Planning

Planning is a necessary part of developing a new product. Time spent using different scenarios will in the long run create a greater chance of success

Project management

The project management and thorough design development ensure greater success when 3d printing the finished product

Fit for purpose

We have a system of checks and tests which are designed to produce data which can be used to verify the capabilities of the product

Why use 3DClever?

We work digitally using secure cloud-based storage, allowing designs to be accessed whenever needed and approved quickly. This streamlined workflow supports rapid prototyping and short-run manufacturing, helping us significantly reduce overall 3D printing project timelines.

We can transform your 2D designs into detailed, high-quality 3D models using Fusion 360. This powerful software enables us to stress-test mechanical components, simulate real-world conditions, and demonstrate the movement and interaction of parts before production.

Design concepts can be turned into fully functional working models in a very short time and at minimal cost, ensuring efficiency without compromising quality.

Our goal is to deliver a high-quality 3D printed product that meets your expectations. Our team is always happy to collaborate closely with you, spending time analysing concepts and developing innovative ideas across a wide range of 3D printing processes and services.

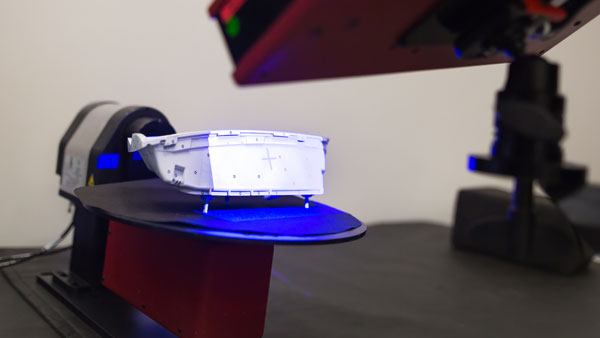

High quality 3D printing facilities

We use SLA (Stereolithography) printing technology, allowing us to produce exceptionally high-resolution parts. With a layer resolution of 25 microns, our prints achieve an outstanding surface finish and fine detail.

Our extensive range of materials enables us to select the most suitable resin or filament for each application. Using advanced 3D design software during the quoting process, we can assess and optimise the strength of the final part to ensure it is fully fit for purpose. This material flexibility gives customers a wide scope when choosing the right solution for their product.

Our printer farm operates 24 hours a day, 7 days a week, allowing us to accommodate urgent and rush orders without compromising quality.

SLA printing delivers an excellent surface finish, significantly reducing or eliminating the need for sanding or post-processing. The extremely fine print layers bond exceptionally well, resulting in smooth, watertight parts. When combined with the appropriate resin, finished components can withstand high temperatures and exposure to toxic or aggressive chemicals.

Thanks to precise layer registration, finished parts show no visible layer lines, producing a smooth, professional appearance. Translucent resins offer a clear finish—while not optically identical to glass, they are sufficiently transparent to allow visual clarity and distinction.

High quality scanning facilities

We offer advanced 3D scanning facilities that allow sculptures to be fully personalised to each customer’s requirements.

We can scan almost any object—human or non-human—and recreate it digitally in our design studio. This digital model is shared for approval before being produced on one of our LFS printers. The result is a truly unique, personal object designed to last a lifetime.

The scanning process takes approximately 10–15 minutes. The only requirement for the subject is to remain still for the duration of the scan. Objects or subjects must be accessible from all angles (360°), and size limitations apply.

The initial print is produced in a single colour. Once complete, it is sent to a specialist partner company for painting and finishing, as this process is not carried out in-house.

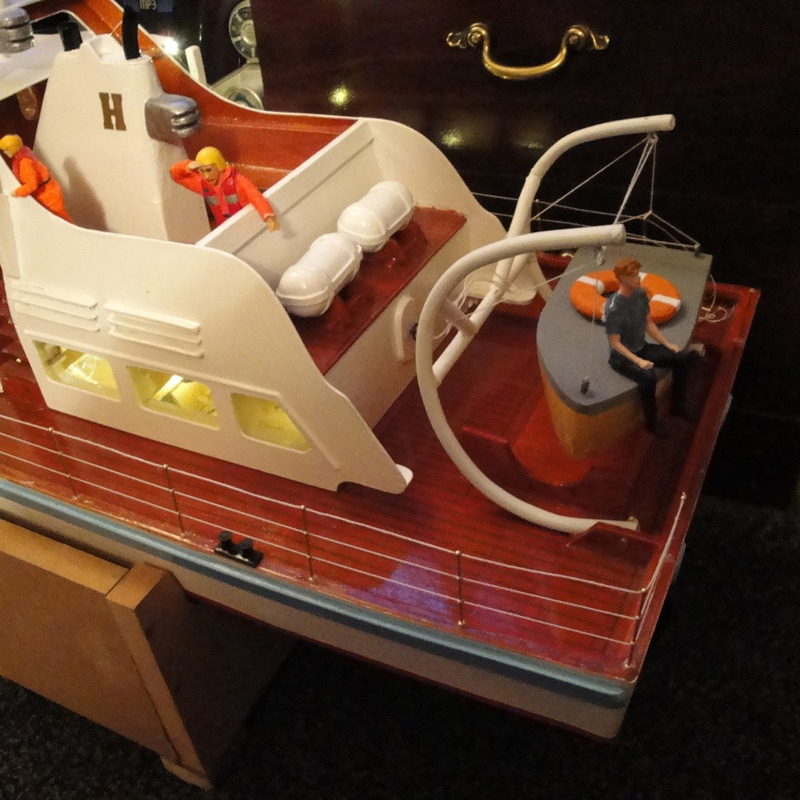

Reproduction of objects

3dClever produces highly detailed scale items with a strong emphasis on historical accuracy. One example is a Polish infantryman figure accurately depicted in a 1939 uniform, faithfully reflecting period-correct equipment and dress.

The company also manufactures scale models for railway layouts, where fine detail is essential to clearly distinguish uniforms, roles, and eras. This level of precision ensures figures remain realistic even at smaller scales.

In addition, 3dClever creates scale components for model boats and aircraft. These include items such as cleats, winches, sailors, and airmen, all designed with the same attention to proportion and authenticity.

Simply provide the required model scale, and 3dClever will produce each item to match exactly, ensuring consistent proportions across all elements of your layout or display.

Get in touch with us today to see how we can help, or visit our shop for a range of pre-printed products