Bespoke 3D printing designs

3DClever produce high-quality 3D printed products for you and your team. See your design concepts be transformed into actual working models. Contact us for a FREE initial assessment, without obligation.

Bespoke designs for your requirements

Planning

Planning is a necessary part of developing a new product. Time spent using different scenarios will in the long run create a greater chance of success

Project management

The project management and thorough design development ensure greater success when 3d printing the finished product

Fit for purpose

We have a system of checks and tests which are designed to produce data which can be used to verify the capabilities of the product

Why use 3DClever?

We work digitally with secure cloud storage, which also means designs can be accessed when needed and approved quickly as part of our rapid prototyping and short rum manufacturing, for us to speed up the 3D printing project time.

We can transform your 2D design into a stunning 3D design using Fusion 360. This software allows to stress test any mechanical parts and to show the movement of parts within the part.

Design concepts can be transformed into actual working models in a very short space of time and with minimal cost.

We aim to produce a high-quality 3D printed product for you and the team is always happy to spend time analysing and developing new ideas on 3D printing processes and services.

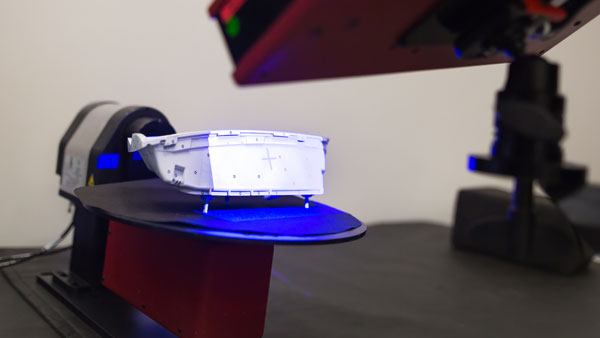

High quality 3D printing facilities

We use SLA printer technology which means we can print high-resolution prints. The layer resolution is 25 microns which gives the final print an excellent, quality finish.

The range of materials we use is extensive and when creating a quote, we can through 3D design software, ensure the strength of the final product is fit for purpose. The resins and filaments, we use give a wide scope to choosing the right material for the product. The farm of printers we have enabled use complete rushed orders as these printers are set up to work 24 hours a day 7 days a week.

SLA printers produce an excellent surface finish which reduces the need to sandpaper or smooth the surface. The print layers are so fine that they produce excellent bonding producing a water-tight finish which when using the correct resin can withstand high temperatures and toxic chemicals.

As the layer registration is so good the finished item does not show layer lines as a result the surface is smooth. Translucent resins produce a clear finish although not as clear as glass. They nevertheless produce a finish which is clear enough to distinguish.

High quality scanning facilities

We have 3D scanning facilities which enable sculptures to be personalised to the customer’s needs.

We can scan any object, human or non-human, and recreate the object in the design studio first. Then, if approved, printed on one of our LFS printers. The final result is a unique personal object which will be timeless. The scanning only takes 10-15 mins, and the only discomfort is for the subject is to be still for the whole 15 minutes. Size is limited and the subject needs to be accessible 360 degrees. The finished print is produced in one colour and then sent to a partner company for painting and finishing. We do not carry out this in-house.

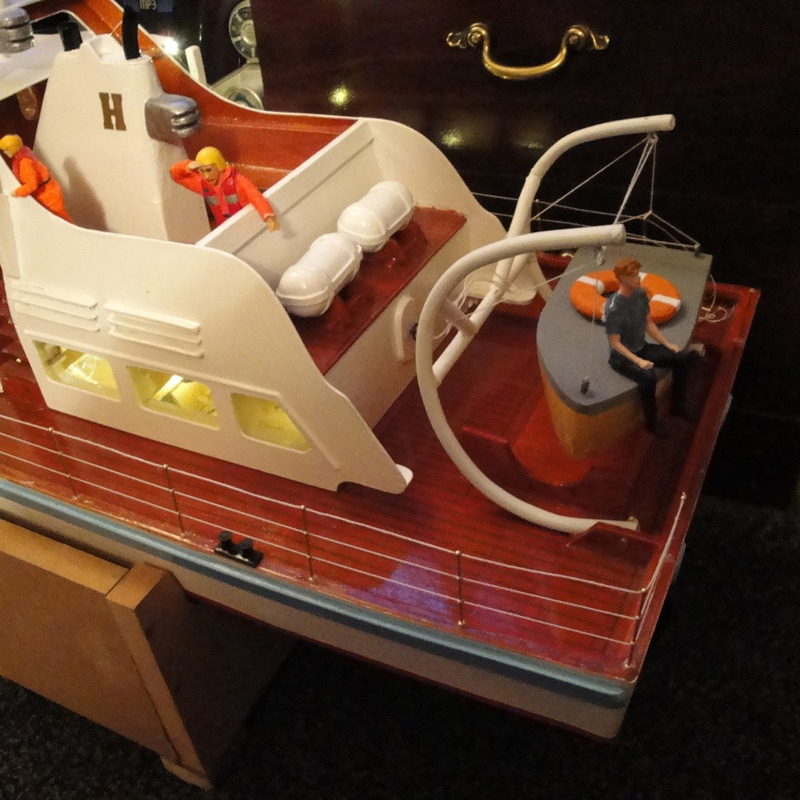

Reproduction of objects

3dClever has produced items with historical accuracies, such as the Polish infantryman who is dressed in 1939 uniform in the enclosed picture.

Scale models have been produced for railway layouts which require great detail so as to distinguish the person’s uniform from one another.

3dclever has also produced scale items for model boats and aeroplanes. Examples of these are cleats, winches, airmen and sailors.

3dclever just needs the scale of the model and then the item can be produced to the same scale, therefore keeping everything in proportion

Get in touch with us today to see how we can help, or visit our shop for a range of pre-printed products