Short Run Manufacturing

Short-run manufacturing is used for products which have a very short product life. Whether this is for reasons of fashion or is seasonal or the market is so small that full-scale production does not make sound financial sense. Therefore, short-run manufacturing is the ideal option to use.

Cost-effective solutions for short-run manufacturing

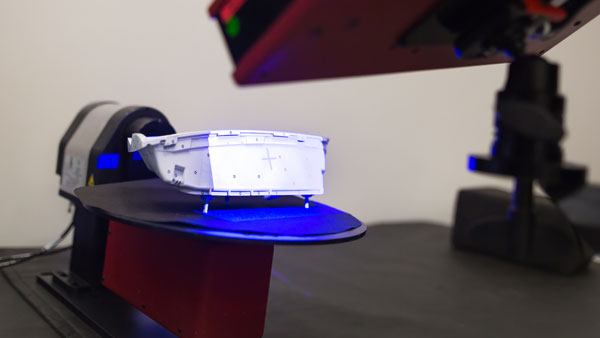

Scanning & 3D printing

Detailed parts can be scanned first then 3D printed

It's in the detail

The detail and ease with which jewellery can be made

Quick replication

Car parts can be replicated cheaply & quickly

Quick turnaround for your 3D Printing requirements

3DClever is a 3D printing manufacturer that can accommodate this facility. 3DClever is a small family-run business which is flexible and capable of delivering products quickly and efficiently to our customers.

With additive manufacturing, it offers very low setup costs and a quick response to design requests. We aim to get the product to the customer what they need when they need it and the quantity they need.

Stocking

Short-run manufacturing is very important for small and medium-scale businesses that do not have the financial strength to carry large stocks of products.

Just-in-time stocking is another example of where short-run manufacturing can be used. The flexibility and cost advantages make short-run manufacturing an ideal solution, and 3D printing is the best method for achieving this.

Manufacturing sectors

The market for this production is very open and 3DClever has supplied architects with small replicates of their designs. 3DClever has also been involved in supplying the vintage car market with various items. Examples of these parts are shown in the shop.

The problem of supply for vintage car restorers is sometimes demand out strips of supply, so 3DClever created a non-locking petrol cap and a locking cap for a Ford escort. We took an existing cap and scanned the cap so it is an exact replica of an actual cap. Vintage car restorers have come to us with specific requirements and generally 3DClever has been able to succeed.

Bridge Manufacturing

Bridge manufacturing is the same as short-run manufacturing and is seen as the bridge between full-scale production and short-run. Specifically, bridge manufacturing relates to parts of a product which may be an update for the part or an add-on.

Designed to meet the requirements

Developing a product involves creating the idea on paper, rather than producing the product and then testing marking the finished item. All these iterations take time and have to be thoroughly checked before going on to the next iteration. Short-run manufacturing is integral to this process, principle in the test marketing area because a small amount of product can give the company an indication of whether the product is going to be successful or not.

Alternative methods of 3D printing

Injection moulding has been the go-to solution for many of the plastic objects produced. It is accurate and consistent however 3D printing had become a serious contender to this production method. Designs supplied in the morning email could be on the 3D printer and back out to the customer by the end of the day. The accuracy of SLA 3D printing is set to 25 microns which for most pieces of work is well within specification. 3DClever would like to call itself a plastic digital manufacturer and with the option of 3d scanning the company can offer a complete solution. The main short-run manufacturing machinery used is adaptive machines such as SLA SLS and FDA With 3dprinting the products get to market faster and the cost of failure is lower.

Painting and finishes

3dclever also offers paint and decorative finished item, e.g., our figures or buildings etc. Reproduction of scenes for a customer involved creating a building to scale and producing figures to the same scale, the finished article was an exact recreation of a new proposed development and potential customers could get a feel for the layout and approach the developer was taking.

3DClever is worldwide

3DClever has supplied products overseas we are always looking for distributors. The versatility of the company means we can support and produce a product which is specific to a country. An example of this has been the production of petrol caps for South African Ford Escorts. The escort produced in South Africa had a slightly different body shell and so a UK petrol cap would not fit on a South African cap.

We can accommodate most industrial sectors and would be pleased if you invited us to quote or opt for a free consultation. A new insight into a problem often yields results and it costs nothing to explore possibilities. Today, manufacturing is global but prototyping and small-scale trials are better controlled locally to the company, this reduces the possibility of communication problems or time issues.

Get in touch with us today to see how we can help, or visit our shop for a range of pre-printed products