Rapid Prototyping

At 3DClever we can produce a design or scan an item and manipulate the scan into an agreed design. Contact us for a FREE initial assessment, without obligation.

Cost and time-effective rapid prototyping

No minimum order

Bring together your ideas quickly. no minimum order requirement

2-day turnaround

A simple and effective process.

2-day turn round

Design assistance

We can assist with your design. Quick scanning service

Why use 3DClever for rapid prototyping?

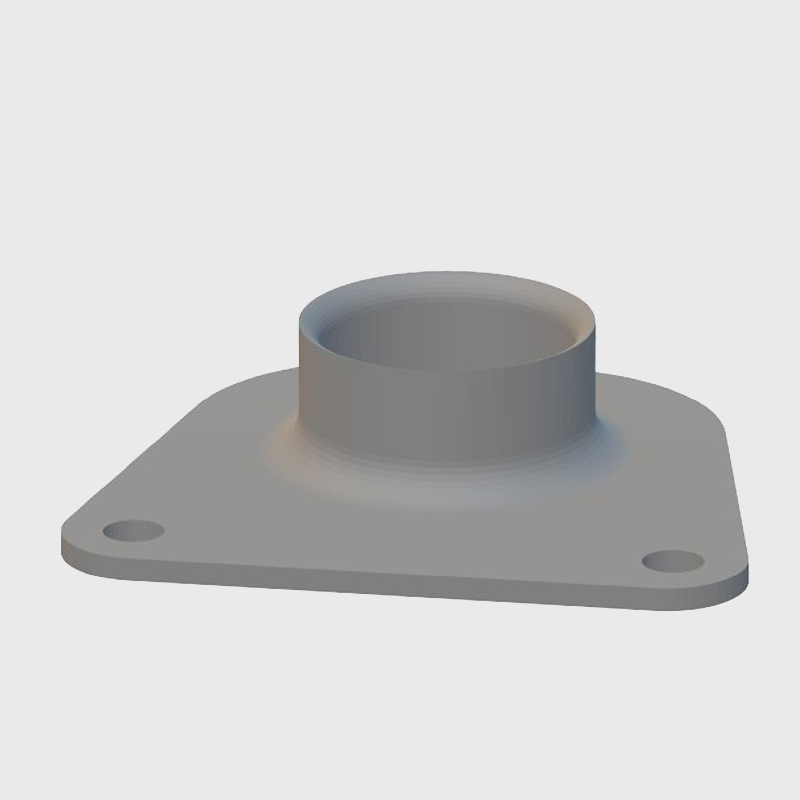

Rapid prototyping allows engineers and designers to quickly create the product they are designing. This process enables alternatives to be created where necessary so as to achieve the finished item which meets the necessary requirements of the design goal. Rapid prototyping has major cost advantages and time advantages, as one-off products can be produced quickly and efficiently without the need for expensive start-up costs.

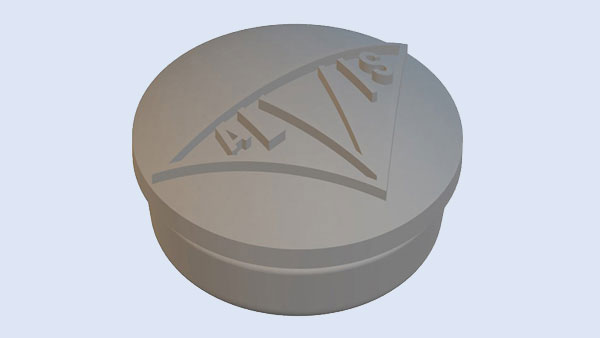

3DClever can produce a design or scan an item and manipulate the scan into an agreed design. 3DClever’s preferred design software is Autodesk 360 and Blender and from this software, one can manipulate size and construction very quickly. Scanning can be used when a product needs to be updated or simply copied and the scanner will give a very accurate representation of the object so the designer has an excellent baseline to work to as the scan is a guarantee of the size and shape of the object.

What is rapid prototyping?

This rapid product development is created by using turnkey technologies. These technologies are designed specifically to facilitate rapid prototyping and to achieve rapid product development. 3DClever is a manufacturer that uses 3D printing to achieve rapid prototyping. 3D printing uses a low-cost product which can be quickly designed and produced within a few days.

The quick turnaround using 3D printing enables rapid prototyping, the lag between changes in design is a few days and so in the event of a product which has challenging requirements the effort and time can be quickly achieved. So, one prototype can be reproduced in many different iterations. These iterations of design rapidly assist designers and engineers to achieve a finished product before moving on to long-term production technologies such as injection moulding and CNC machinery.

Research is another area where rapid prototyping methods can achieve the answers an engineer is striving for in a cost-efficient quick solution.

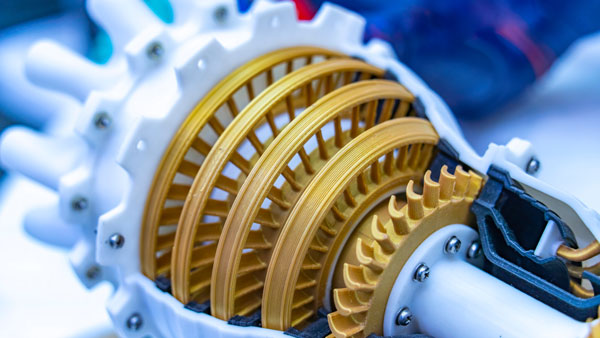

3DClever 3D print farm

We use SLA technology which offers an enormous range of materials for rapid prototyping. Clear, coloured, heat resistant, flame resistant, flexible, rubber-like properties, and some materials are immensely strong. All these materials can be used in the process of rapid prototyping.

Pricing

We are a small family-run business which allows us to keep costs down because projects will be handled by a small number of people. When using rapid prototyping it is important not to be stalled by large manufacturing lag. At 3DClever you are not passed around different departments so the net result is you are constantly aware of where your product is when dealing with 3DClever.

Fast delivery of finished product

We can guarantee a fast turnaround of our product because the advantage of a small company has the flexibility to allow quick response to the customer needs.

3DClever holds in high esteem its customer feedback and maintaining good customer relations is very important to us.

3DClever Quality Control

Before the product is produced part of the production process is to agree tolerances for the finished product. 3DClever will not supply a product which does not meet these tolerances as before the product leaves the factory tests are made to ensure the product has met the required specification. Rapid prototyping must produce a product which is consistent and accurate so in the event of the product going into a main manufacturing process, the end result is the same as the one which was produced via rapid prototyping.

What methods can 3DClever offer for rapid prototyping?

3DClever uses Stereolithography (SLA) in creating products through rapid prototyping methodology. This method of 3D printing is very functional, versatile and gives a clear and accurate finish. Prints produced in this type of printing can be drilled and sanded

We also offer selective laser sintering (SLS) which gives even better mechanical properties than SLA. The printers we use can handle larger sizes than our existing range of SLA printers.

CNC machining is mainly used on very large objects that are required to be made from metal. There is a case for making a part from plastic and then moving the production over to CNC and making the finished example out of metal.

This is the essential function of rapid prototyping to produce, test and redesign a product which can be produced in high volume quantities so the result will be a product which is fit for purpose. Additive manufacturing has major advantages when considered rapid prototyping. No other method of manufacturing can give product developers a range of options at such a low cost.

Get in touch with us today to see how we can help, or visit our shop for a range of pre-printed products